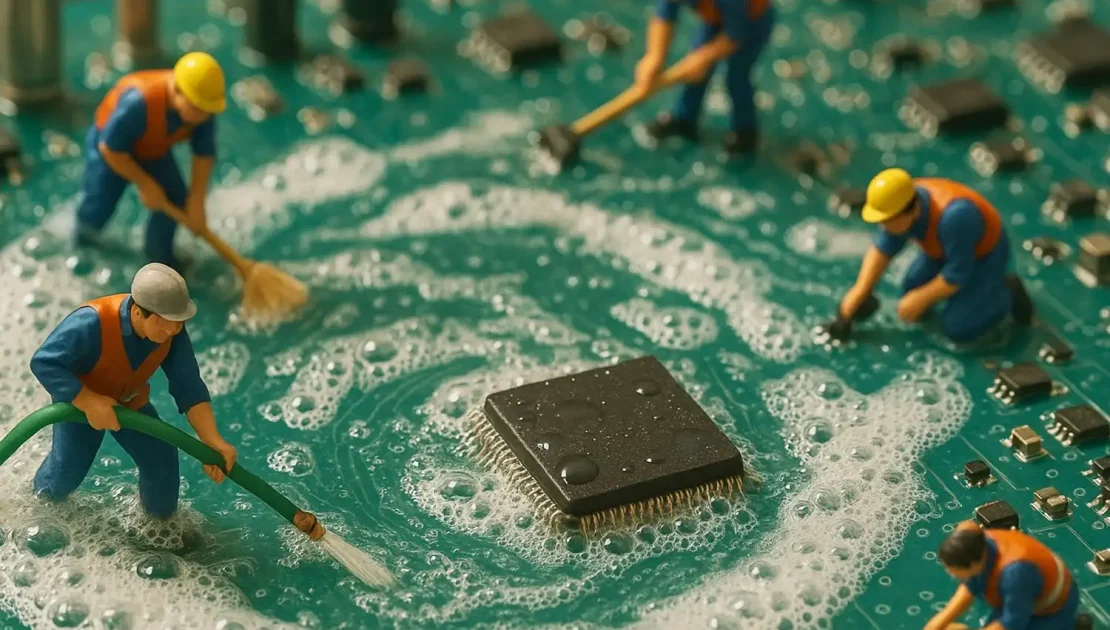

A Handy Guide for Cleaning Circuit Assemblies

Why Clean Circuit Assemblies?

Cleaning circuit assemblies is no longer a niche requirement reserved for military or medical devices. In today’s high-reliability electronics landscape, cleaning is vital for ensuring performance, reducing failures, and complying with modern standards. This guide condenses expert insights from Michael Konrad’s white paper into an actionable, blog-friendly format tailored for Etek Europe readers.

The Hidden Risks of Flux Residues

When flux is used during soldering, it helps improve joint quality. But once the job is done, any leftover residue becomes a contaminant. These residues are:

- Conductive and corrosive, especially under humid conditions

- Prone to form dendrites, which can cause circuit failures

- Inconsistent with high-reliability application standards

The Evolution of Cleaning in Electronics

From the dominance of CFC-based solvents pre-1989 to the rise of “no-clean” flux, the industry has swung like a pendulum. However, modern challenges like:

- Miniaturisation

- Lead-free solder requiring higher reflow temps

- Higher reliability expectations are leading to a resurgence in cleaning practices.

Understanding the Defluxing Process

What is Defluxing?

Defluxing is the removal of flux residues post-soldering. It typically involves four stages:

- Wash: Solubilise flux with a chemical wash

- Rinse: Remove wash solution and residue

- Cleanliness verification: Ensure no contaminants remain

- Dry: Prepare the board for further processing

Cleaning Challenges in Contract Assembly

Managing Variability

Contract manufacturers often face:

- Mixed processes and flux types

- Inconsistent cleaning requirements

- Pressure to deliver pristine assemblies regardless of input quality

Critical Factors When Choosing a Cleaning Process

Factors to Consider

- Type of flux: No-clean flux needs chemical cleaning agents

- Assembly type: SMT requires more precision than through-hole

- Volume & throughput: Affects machine choice

- Budget: Cleaning costs vs failure costs

- Environmental regulations: Discharge limits and sustainability

How Clean is Clean Enough?

Cleanliness Standards and Testing

The popular “How clean is clean?” has no single answer. Key points:

- ROSE testing is common but not all-encompassing

- Consider board density and operational environment

- Lower contamination tolerances for smaller, high-reliability assemblies

Environmental and Economic Impact

Greener Cleaning Technologies

Modern cleaning systems focus on:

- Reducing water and energy use

- Minimising chemical waste

- Enabling zero-discharge configurations

The Rush to Clean “No-Clean”

Ironically, no-clean fluxes are now the most commonly cleaned. Why?

- Higher failure rates due to miniaturisation and poor residue encapsulation

- Electrical leakage and dendritic growth risks

- Increasing expectations from commercial markets mirroring military standards

Conclusion

Cleaning circuit assemblies is no longer optional in many cases—it’s an essential part of ensuring product reliability, compliance, and customer satisfaction. As technology advances, so must our commitment to cleanliness.